- Home Page

- Company Profile

-

Our Products

- Drain Board/ Protection Board

- Geotextile

- Nonwoven Geotextile Fabric

- Coir Mat

- Geo textiles Fabric

- Non Woven Geo Bag

- Nonwoven Geotextiles

- VT 1300 (POLYPROPYLENE / PET WOVEN GEOTEXTILE FABRIC)

- Geotextiles For Tunnels

- Road Geotextile

- Railways Geotextile

- SAMI layer for asphalt reinforcement

- Paving fabric

- Nonwoven Geotextiles Spunlace 100 % Polyester

- Geobags Headers

- Draincells

- Fibreglass Mesh

- Geomembrane

- Geocomposite Findrain

- Geo Tube

- GeoGrid

- Geocell

- VT STRIP

- Plastic sheets

- Plastic Grass Pavers

- Extra Links

- Contact Us

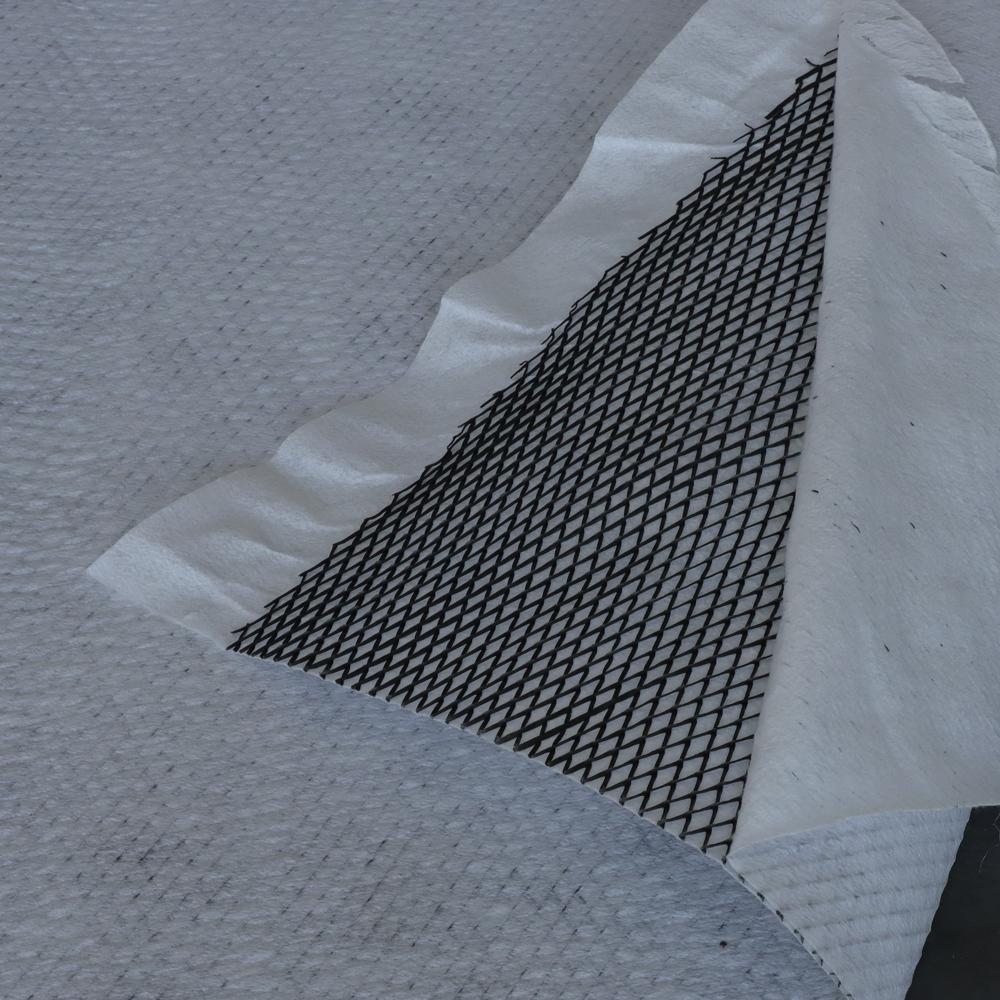

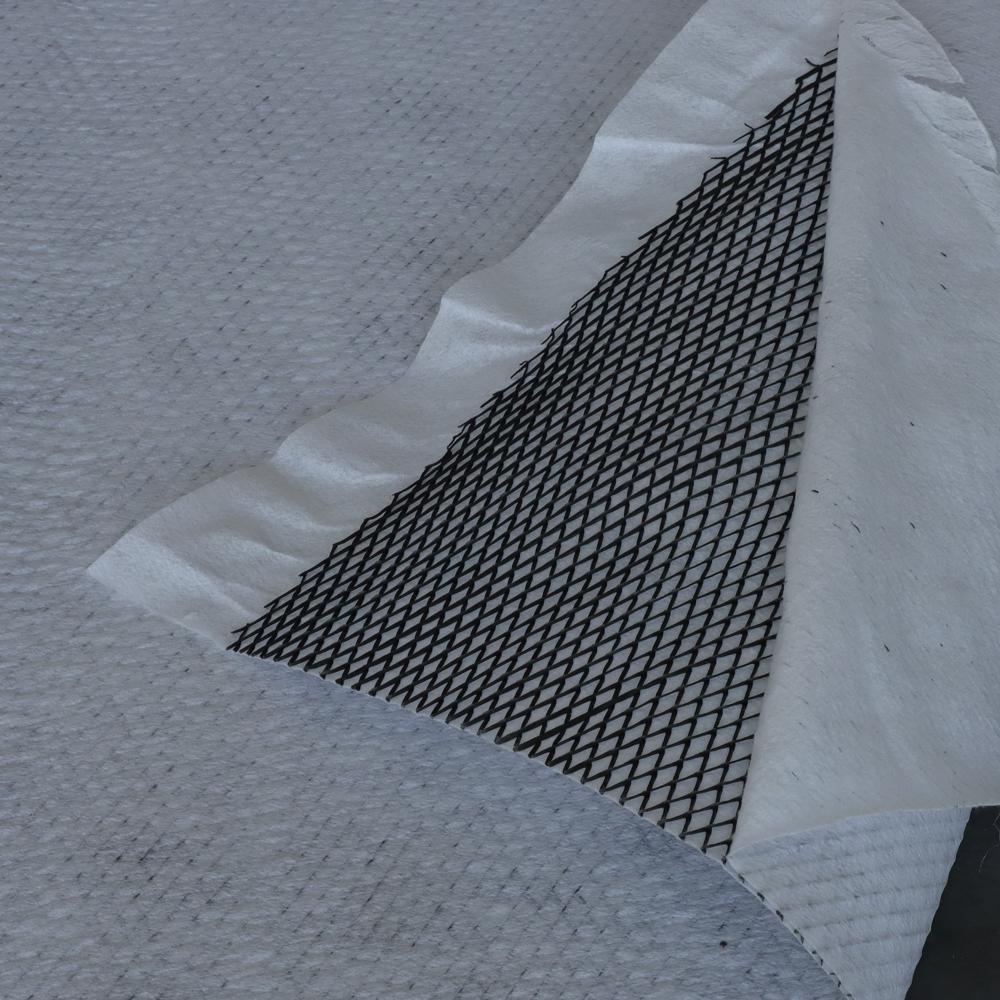

Geo Composite

120.0 INR/Square Meter

Product Details:

- Material PP

- Usage & Applications Industrial

- Color Black

- Georgette Texture Plain

- Characteristics Light in Weight

- Application Geo Composite

- Click to View more

X

Geo Composite Price And Quantity

- 500 Square Meter

- 120.0 INR/Square Meter

Geo Composite Product Specifications

- Black

- Plain

- Light in Weight

- Geo Composite

- PP

- Industrial

Geo Composite Trade Information

- 50000 Square Meter Per Day

- 1 Week

- No

Product Description

We are manufacturer & supplier ofGeo Composite FromNoida, India. We are supplyingGeo Compositeto our valuable clients allacross India. We are manufacturing high qualityGeo Compositeto give satisfactionto our esteemed clients.

Call for best qualityGeo Composite.

Geocomposites are engineered materials composed of two or more different types of geosynthetic components combined to create a single product with specific functions and properties Geosynthetics are synthetic materials used in geotechnical and civil engineering applications to enhance soil and structure performance Geocomposites offer a way to combine the benefits of different geosynthetic materials to address multiple functions within a single product

The components that make up a geocomposite can include various types of geosynthetics such as geotextiles geogrids geomembranes geonets and more These components are combined through different manufacturing processes to create a material that provides a range of functionalities

Common types of geocomposites and their applications include

1 GeotextileGeonet Geocomposites These combine the filtration and separation capabilities of geotextiles with the drainage capabilities of geonets They are often used for drainage applications in areas with high water flow such as retaining walls landfills and roadway drainage systems

2 GeotextileGeomembrane Geocomposites Combining the filtration properties of geotextiles with the barrier properties of geomembranes these geocomposites are used for applications requiring both filtration and containment such as landfill capping and impoundment liners

3 GeotextileGeogrid Geocomposites These combine the reinforcement properties of geogrids with the separation and filtration capabilities of geotextiles They are used in applications such as soil stabilization embankment reinforcement and retaining walls

4 Drainage Geocomposites These typically consist of geotextile and drainage core components They are designed to efficiently collect and transmit water making them suitable for applications like subsurface drainage systems and vertical drainage behind retaining walls

5 Pavement Geocomposites These are used in road construction to provide separation reinforcement and drainage functions within a single product They can enhance the performance and durability of pavement structures

Benefits of geocomposites include

Multifunctionality Geocomposites can perform multiple functions within a single product reducing the need for multiple separate materials

Efficiency By combining different geosynthetic components geocomposites can streamline installation processes and potentially reduce costs

Customization Geocomposites can be designed and tailored to meet specific project requirements and performance criteria

Improved Performance Geocomposites can provide enhanced performance compared to using individual geosynthetic materials separately

Space and Weight Savings Using geocomposites can reduce the overall volume and weight of materials needed for a project

Geocomposite selection should be based on the specific needs of the project considering factors such as soil characteristics hydraulic conditions load requirements and environmental considerations Proper installation and adherence to manufacturer guidelines are essential to ensure the geocomposite functions as intended

Efficient Lamination for Industrial Strength

Our geo composite woven bag benefits from advanced lamination technology, enhancing its structural strength and resistance while maintaining a lightweight profile. The glossy finish not only improves visual appeal but also adds an extra protective layer, making it suitable for challenging industrial environments. With versatile applications, these bags are trusted by industries requiring reliable and durable storage and containment solutions.

Why Choose Black PP Geo Composite Bags?

The choice of polypropylene material ensures exceptional longevity and chemical resistance, while the black color adds UV protection, making it ideal for outdoor and industrial geo composite usage. The plain georgette texture enables easy handling and stacking, simplifying industrial processes. Manufactured in India, our bags meet both local and international supply needs with consistent quality and prompt delivery.

FAQs of Geo Composite:

Q: How is the lamination process applied to the woven Geo Composite bags?

A: The lamination process involves applying a thin protective film onto the woven polypropylene bag surface, creating a glossy finish that enhances durability, water resistance, and overall strength for industrial applications.Q: What makes this geo composite bag suitable for industrial usage?

A: The bags lightweight, robust structure, and glossy laminated surface make it ideal for demanding industrial environments. It provides resistance to moisture, chemicals, and UV rays, ensuring safe containment and transport of materials.Q: When should I use the black PP geo composite bag with lamination?

A: These bags are recommended whenever you require reliable containment or transport in geo composite projects, especially in scenarios where resistance to environmental factors and lightweight handling are crucial.Q: Where can geo composite bags be utilized in industry?

A: Geo composite laminated bags are widely used in civil engineering, construction, mining, and waste management industries for storage, containment, and protection of various materials.Q: What is the benefit of the glossy surface treatment on these bags?

A: The glossy treatment not only adds visual appeal but also enhances protection against abrasions and moisture, prolonging the lifespan of the bag in harsh working conditions.Q: How does the plain georgette texture impact bag usage?

A: The plain georgette texture promotes easy handling, stacking, and movement of the bags, making them practical for industrial logistics and material management.Q: Are these geo composite bags available for export from India?

A: Yes, as a trusted Indian exporter, manufacturer, and supplier, we offer geo composite laminated bags to domestic and international customers with adherence to global quality standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free